By Michael Hermann | Oct 10, 2014

Getting to first time right is a key goal at Nuvation Engineering and is built into our electronic design methodology. Broadly speaking, it means two things: First, when you design and build new hardware, your methodology delivers new boards with zero cuts and jumps. You may need to still tweak a component value or two or change component population options, but you’ve avoided those problems that would require a board re-spin. Second, your first board spin has NO architectural or serious performance issues that would require a re-spin before transitioning to volume manufacturing. So basically “First Time Right” means “no board re-spin required.” This helps your project stay on budget, on schedule, and maybe even ahead of the curve on both of those critical KPIs.

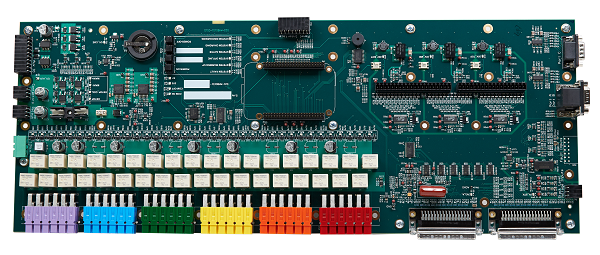

for large-scale liquid metal battery.

Let’s be up front about one thing so my fellow engineers don’t call me out here – first time right design isn’t about trying to get to the highly unlikely outcome of being able to take your very first layout to long-term manufacturing without making any changes along the way. That’s just almost never going to happen, and if it did you just got lucky (in terms of long-term optimization needs), that’s all. Realistically, a First Time Right board will very likely still require minor layout updates as you proceed toward the volume manufacturing process – optimizations are to be expected for reasons of test, manufacturing cost, system integration, and other considerations.

Benefits of First Time Right

Three of the most important benefits are schedule, cost, and confidence. Schedules gets shorter in the long-run because major design changes (remember, don’t confuse First Time Right with “first time perfect”) cost a lot of time and money.

Regarding confidence, in engineering we’ve always got customers – very directly when you’re an electronic design services company like Nuvation Engineering, but an internal engineering team is accountable to customers too. Product management, sales, marketing, manufacturing, executive management – these people/groups are all looking for, and counting on, outcomes from Engineering. So whether internal or external, an engineering team with a First Time Right approach is going to be better able to instill confidence in the many stakeholders who are dependent on Engineering’s success. First Time Right outcomes can, apart from helping your job security, increase cooperation and collaborative problem solving and improve performance outcomes across departments, or even across whole organizations. It’s sometimes hard to measure all these benefits, but we can certainly say that First Time Right outcomes reach beyond just the project scope, budget and schedule.

5 Proven Principles to Reach First Time Right

So how do you get to First Time Right? While there are many techniques, I will discuss what I have found to be some of the most important guiding principles. By “principles,” I mean how one approaches the work – the work itself would cover things like simulations, tolerances, flexibility/expansion approaches, etc., all very important things which I may write about sometime, but not here today.

1) Up-Front Planning and Design

Every board spin of even a moderately complicated design will cost weeks of schedule time and a multitude of engineering hours. Investing some time up front on rigorous planning and design can save you much more damaging schedule and cost overruns later in the project.

At Nuvation Engineering we distinguish design as happening at the document level, which is why we write detailed Hardware Design Descriptions (HDDs) before jumping into schematics. In the HDD you select your major components, figure out your reset sequencing, your I/O, your clocking, and so on (it’s quite a long list). All these kinds of things need to be thought through before you’re drawing schematics, or you’re going to be wasting a lot of time redoing work.

2) Peer Review

This is perhaps one of the most fundamental principles at Nuvation Engineering. We consider engineering to be a team sport, and your peers are your teammates. We do peer reviews both informally and formally: “Informally” means we encourage engineers to go to their colleagues for consultation, input, and problem-solving – don’t be a lone wolf. “Formally” means we do reviews before designs proceed to the next stages – we do those reviews at the design level (see below for what I mean by that), as schematics near completion, and at multiple points during PCB layout (usually in the placement and routing phases).

3) Signoffs

Nuvation Engineering leverages some of the best value points from phase-gate project management methodologies. This includes having several points during a project where we ask ourselves and our customers respectively for signoff. This feeds into peer review too. When you ask somebody to sign off on something and really say “I approve it,” this ups the ante.

4) Hardware is Not an Island

At Nuvation Engineering hardware, software and FPGA engineering are a combined group. If you don’t have these disciplines working together, you’re going to have architectural problems. A practical application of this principle is to have the hardware teams get their requirements design document(s) and schematics reviewed by the embedded software team. The software engineers don’t need to possess the skills required to do the hardware work themselves, but at the interaction points they must be able to contribute at a level that can corroborate the quality of the design and help improve upon it; members of great teams understand each other’s work.

5) There are no Junior Engineers

At Nuvation Engineering we don’t have “junior” engineers – once you’re on the team, you’re a “Staff Engineer” and you grow from there. Entry-level engineers bring a highly valuable questioning approach; without years of “doing it that way,” they are unburdened with the past – they can come from curiosity and tend to question more.

We've chosen to harness these fresh ways of looking at engineering and we actively value the contributions of our recently graduated engineers, hence the term “Staff Engineer.” A good engineering group embraces fresh and new perspectives; to think you know it all is just plain arrogance.

Collaboration

To sum, First Time Right design is achieved through collaboration across disciplines (peer review), rigorous planning and documentation, accountability (sign-offs), and valuing the contributions of all staff engineers regardless of seniority. The major KPIs impacted are schedule, cost, and confidence. Of course there are many other aspects to an engineering approach that achieves a First Time Right design; for example, working with highly talented engineers is certainly a big part of it – but at the end of the day two teams with equal skill can produce different outcomes, depending on how they work together, and the principles they follow to achieve First Time Right electronic design.