About Us

Standards & Certifications

What We Do

Ensuring compliance at every stage

Proven Track Record

Over 1,000 successful projects delivered across every major market vertical and application type.

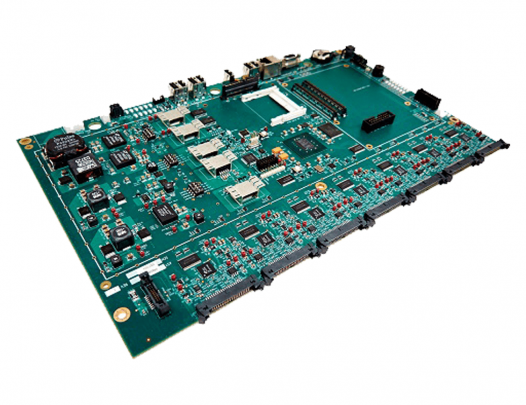

End-to-End Development

We handle everything from design and testing to manufacturing and certifications, seamlessly.

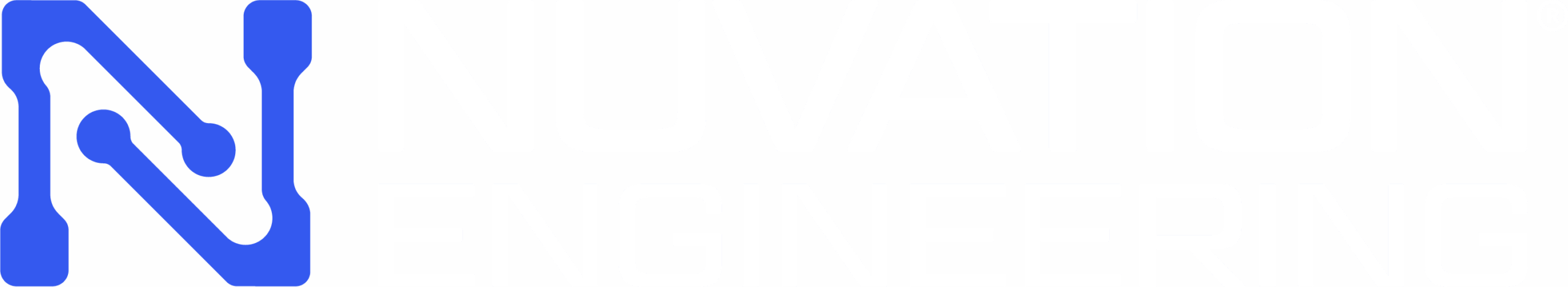

Built for Any Environment

From medical to automotive, aerospace to industrial, we design for the most demanding conditions.

Regulatory Expertise

We navigate certification and compliance for life-critical, safety-sensitive, and high-risk devices.

Our Expertise

Regulatory & Industry Mandated Standards

Safety Testing and Certification

- We work with Nationally Recognized Testing Laboratories (NRTLs), e.g. CSA, Intertek, TUV, UL

- US and Canadian emissions compliance, e.g. FCC US 47 CFR Part 15 Subpart B & C, Canadian ICES-001, ICES-003

- CE Declaration of Conformity

- Safety Testing and Certification: We can work with Nationally Recognized Testing Laboratories (NRTLs), e.g. CSA, Intertek, TUV, UL US and Canadian emissions compliance, e.g. FCC US 47 CFR Part 15 Subpart B & C, Canadian ICES-001, ICES-003 CE

- IEC/EN 60601-1 (medical electrical equipment)

- IEC 60730-1 (automatic electrical controls)

- IEC 61010-1 (electrical equipment)

- IEC 62368-1 (audio/video, information and communication technology equipment)

- UL 1973*

- UL 9540*

- Intentional Radiator Testing for Bluetooth Low Energy (BLE) and Wi-Fi

- Unintentional Radiator Testing

- *Nuvation is represented on these UL technical committees and supports the creation of new additions to the standard.

Environmental Testing

- Temperature

- Relative Humidity

- Shock

- Vibration

- HALT

- Transportation (ISTA-2A)

- Water and Dust Ingress

International Manufacturing Standards

- All of our contract manufacturing partner facilities are ISO 9001 certified. Specialized assembly can be done under these certifications:

- AS9100 (Aerospace)

- ISO13485 (Medical)

Our Projects