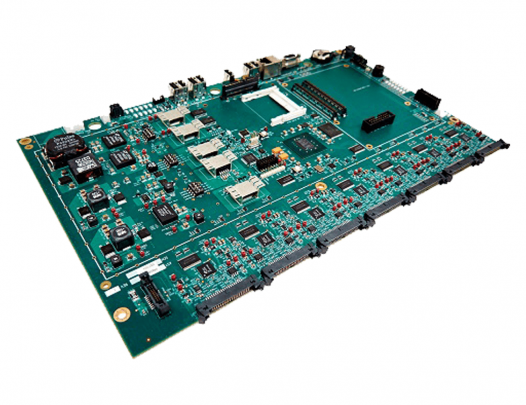

Our Services

New Product Introduction

What We Do

Accelerating the path from design to production

Design for Manufacturing

Manufacturing requirements are built into the design from the start to streamline production.

Optimize the Supply Chain

A complete, end-to-end supply chain is established and optimized to support manufacturing.

Compliance & Packaging

Certifications, packaging design, and other back-end stages are managed as part of the process.

Production Engineering

Detailed engineering ensures the product is ready for reliable, high-volume manufacturing.

Process Definition

Fabrication, assembly, testing, and quality systems are clearly defined and documented.

Pilot to Ramp-Up

Pilot builds and ramp-up are managed to ensure a smooth shift into volume production.

Our Experience

New Product Introduction Expertise

- Incorporating specific manufacturing requirements into the design process

- Establishing and optimizing an end-to-end supply chain to facilitate manufacturing

- Back-end design stages e.g. compliance certifications, packaging design

- Manufacturing engineering to prepare the design for volume production

- Defining fabrication/assembly/configuration, test, and quality systems

- Production pilot, ramp, and management of entire production process

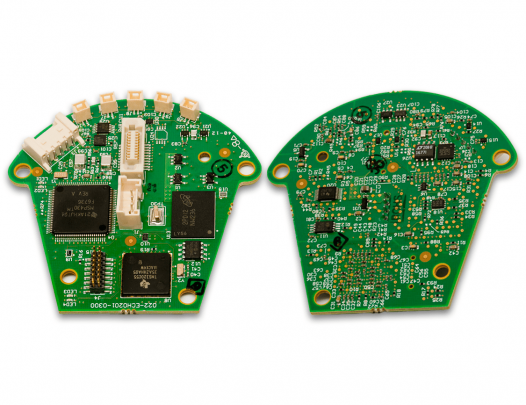

Transition to Manufacturing Expertise

- Initial Manufacturing Engagement (IME) documentation to establish the appropriate test fixture design, product validation and product certification strategies: Manufacturing Test Plan (MTP), Manufacturing Test Verification Plan (MTVP), Manufacturing Readiness Test Plan (MRTP), and Manufacturing Work Plan (MWP)

- DFx reviews to ensure testability and manufacturability of product

- Manufacturing test fixture software development based on test fixture design

- Manufacturing test fixture hardware design and fabrication based on test fixture design

- Manufacturing test fixture verification and installation at the CM responsible for product assembly

- Create a manufacturing test manual for product

- Coordination of the product packaging design

- Create an assembly guide for product

- Perform component engineering and hierarchical BOM management

- Oversight of regulatory testing

- Product Validation Testing

- Oversight of pilot production builds as a transition to volume production

Our Projects