Our Applications

Industrial Automation

What We Do

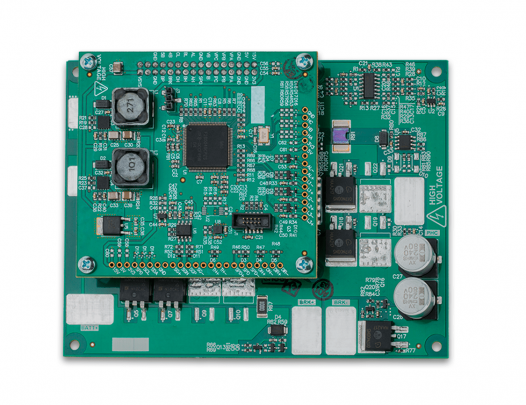

Innovative control systems for next-gen industrial platforms

Precision Control Systems

High precision, accuracy and reproducibility through advanced control algorithms, sensor interfacing and filtering, and actuator control.

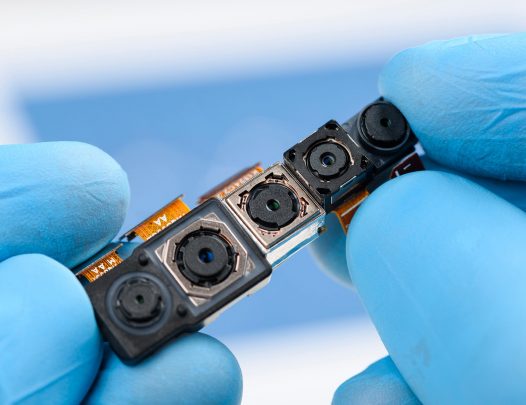

Sensor Integration

Sensor analog front-end, analog and digital filtering for a large range of electro-mechanical and optical/image sensors.

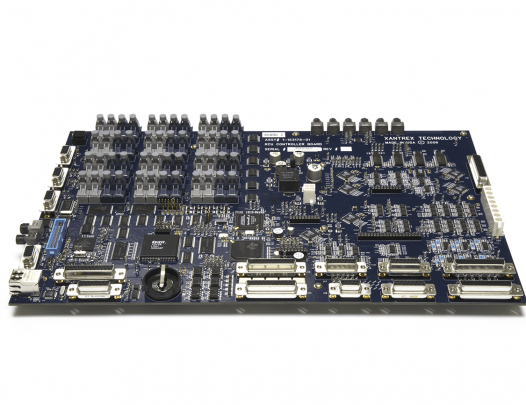

Advanced Motion Control

Includes motion sensing and actuation, including encoders, LIDAR, Sonar, and linear or rotational motors.

Accelerated Computing

Designs incorporating DSPs and FPGAs to enable real-time performance in control applications.

Full Lifecycle Support

From architecture and feasibility to validation and deployment, we support every development phase.

Low-Latency Networking

Fast, reliable communication networks built for high-speed industrial automation environments.

Our Experience

Industrial Automation Expertise

- Machine Vision and LIDAR

- Distributed system design

- Synchronous distributed motor control

- Diverse protocols such as EtherCAT, Modbus, DNP3, ZigBee, Ethernet/IP, CAN, RS485, etc.

- EtherCAT high-reliability control (up to 10k nodes)

- DSP & FPGA accelerated processing and control

- Custom control algorithm design

- Connectivity for local or cloud based configuration, logging, display, notification, and control

Our Projects