Welcome to the Nuvation Garage

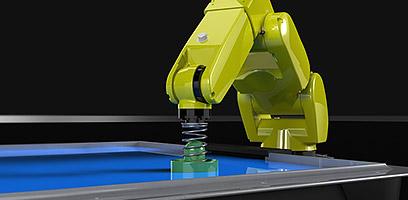

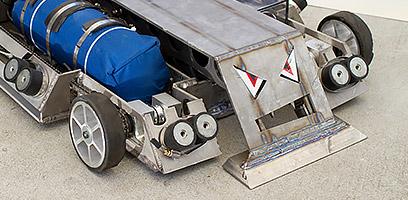

The Garage is an 1800 square foot garage inside Nuvation's Sunnyvale Headquarters. Engineers work on cool projects there in their free time, creating new things that usually were conceived over beer and pizza some time before. Yes, in our spare time, Nuvation engineers stop engineering for fun and money, and start engineering for fun alone. We've made things like combat robots, an electric car, an autonomous driving electric beer keg, a robot that plays air hockey, and other arguably useful inventions that require an incredible amount of engineering expertise to make them work!

The Garage is equipped so after hours our engineers can explore passion projects and develop their skills, check out what they’ve been working on lately: